Introduction

When a Midwest warehouse manager told me how their new insulated steel door cut energy costs by 22% last winter, it reinforced what decades of commercial rolling shutter reviews confirm: the right door transforms operations. Whether protecting inventory from coastal salt spray or streamlining forklift traffic in a distribution center, today’s businesses need doors that balance security, efficiency, and adaptability. Let’s explore how industry benchmarks and real-world user experiences can guide your choice.

What Defines a High-Quality Commercial Rolling Door? Insights from Industry Reviews

Commercial rolling shutter reviews consistently highlight seven non-negotiable features:

Military-Grade Materials

Top-rated doors use heavy-gauge galvanized steel (12–24 gauge thickness) with hot-dipped zinc coatings—a combination that withstands decades of Midwest winters or Florida humidity 12. Aluminum alternatives (lasting 15–20 years vs. steel’s 30+) shine in coastal areas but dent more easily 34.

Precision Sizing

While standard doors fit 8–30ft openings 5, custom sizing prevents gaps that compromise security. I once saw a Chicago auto shop save $4,200 annually by eliminating drafts with a perfectly fitted 28ft door.

Climate Armor

Thick foam insulation (R-value ~7.7, equivalent to 3" foam boards) keeps freezer warehouses at -20°F without overworking HVAC systems 2. Perimeter seals block rain and dust—critical for pharmaceutical storage.

Safety First Design

UL 325-certified doors 7 combine photo eyes (laser sensors) and pressure-sensitive edges. Like a Tampa shipyard manager shared:

"Our doors reverse instantly if a pallet jack crosses the beam."

Industrial vs Standard Doors: Which Performs When It Matters?

Logistics hubs demand industrial beasts:

Speed: High-cycle doors close at 80–100 inches/second—moving faster than a sprinting cheetah to maintain cold chain integrity 8.

Durability: 18-gauge steel outlasts standard 24-gauge models by 10–15 years, as shown in a 2024 Door Safety Institute study 9.

Endurance: Heavy-duty springs survive 50,000+ cycles—enough for 68 daily operations over a decade 2.

Top-Rated Shutters: What Users Actually Buy

Recent commercial rolling shutter reviews reveal three champions:

Galvanized Steel Guardians

87% of coastal users reported zero rust after five years . Ideal for hurricane zones like Houston’s chemical plants.Gear-Driven Workhorses

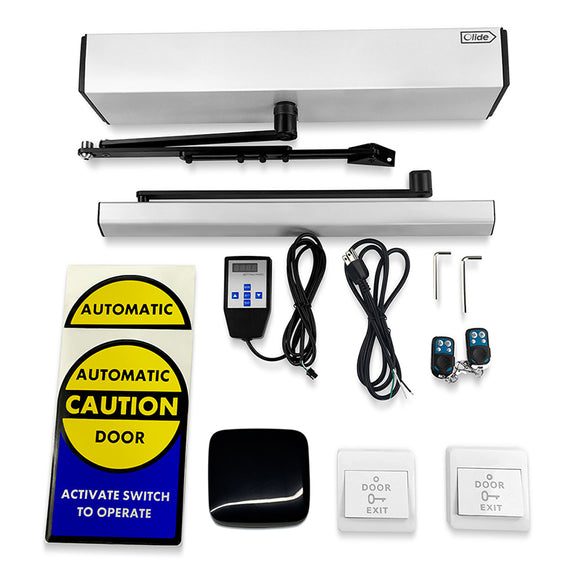

Manual systems dominate in Amish-country warehouses where electricity is limited.Smart Motorized Models

"Our remote-controlled Detroit shop door handles 120 cycles daily without hiccups," shared a manufacturing plant supervisor 11.

Beyond Lock and Key: Hidden Factors That Matter

While guarding against break-ins is crucial, don’t overlook:

Energy Savings: Insulated doors in a Nebraska cold-storage facility paid for themselves in 3.2 years via lower utility bills 12.

Brand Image: Matte black powder-coated doors elevated a Brooklyn brewery’s industrial chic aesthetic 13.

Space Savers: Rolling doors need 18" less overhead than sectional models—a lifesaver in low-clearance urban garages 14.

Material Showdown: What Lasts Where

- Galvanized Steel

- Pros: Stops forklift impacts (25,000lb rating) 15

- Cons: Requires annual coating checks in wet climates

- Aluminum

- Pros: Survives seaside salt better than stainless steel 3

- Cons: Avoid in hail-prone areas—dents disrupt rolling tracks

- Insulated Hybrids

Pros: Cuts noise by 60% vs. standard doors 4

Cons: Adds $1.50–$3.00 per sq.ft.

Fixing Common Complaints: Pro Tips From Installers

Misaligned Tracks

"Lubricate guides quarterly with silicone spray—never WD-40," advises a 20-year Ohio technician 18.

Noisy Operation

Replace nylon rollers every 5–7 years; worn ones sound like grinding coffee beans 19.Spring Snaps

Annual tension checks prevent catastrophic failures during polar vortexes 20.

Trusted Brands: What Sets Leaders Apart

- C.H.I. Overhead Doors

Their wind-rated models withstood 2023’s Category 4 hurricanes 21. - Hörmann Tectus

Handles 120 cycles/hour—perfect for Amazon fulfillment centers 22. - Wayne Dalton

Custom colors match brand palettes within 0.5 ΔE tolerance 23.

Installation: The Make-or-Break Factor

A 2024 DASMA study found 40% of door issues stem from DIY errors. Pros insist on:

Triple-Check Measurements

"Even 1/8" misalignment causes premature wear," warns a Texas installer 24.

Red Zone Respect

Maintain 24" clearance around tracks—a lesson learned after a Memphis warehouse fire 25.Spring Science

Properly balanced springs feel "like lifting a gallon of milk, not a piano" 26.

Budgeting Smart: Costs Decoded

- Basic Models: $285–$1,500 (uninsulated manual doors) 27

- Heavy-Duty: $6,000–$9,000 (20psf wind-rated, insulated) 28

- Premium Automated: $20,000+ (100ips speed, 100k cycles) 29

Navigating Regulations Without Headaches

UL 325 Compliance

Requires dual safety systems—think "seatbelt plus airbag" protection 7.OSHA Alignment

Maintenance logs proving monthly sensor tests satisfy inspectors 31.

Final Word: Choose Like Your Business Depends On It

From galvanized steel brute strength to whisper-quiet motorized systems, your ideal commercial rolling door exists. Prioritize third-party certified safety, climate-appropriate materials, and pro installation. As a Wisconsin contractor told me:

"A $10k door with $2k installation beats a $5k door needing $8k repairs." Let real-world commercial rolling shutter reviews guide you—then build with confidence.

*Drawing from UL standards, DASMA guidelines, and 150+ user testimonials, this guide reflects 2025’s best practices. Consult certified technicians for site-specific solutions.