In the quest to balance functionality with curb appeal, plywood garage door panels have emerged as a versatile choice for homeowners. These doors offer natural warmth, durability, and customization that synthetic materials struggle to match. If you’re renovating a historic property or crafting a modern home, understanding how to select, install, and maintain plywood garage doors ensures lasting performance without sacrificing style. Drawing on industry insights and 2025 trends, this guide covers every step, from material choices to climate-proofing strategies.

Why Plywood Garage Door Panels Outperform Metal

Plywood’s adaptability and structural integrity make it a standout option. Let’s explore its advantages over steel, aluminum, and composite alternatives.

Built to Last

While steel resists dents better, plywood panels outperform aluminum and some composites in impact resistance. They’re less prone to warping and won’t rust like metal options 1. When sealed properly, exterior-grade plywood also withstands moisture better than solid wood, reducing rot risks 2.

Energy Efficiency

Energy Efficiency

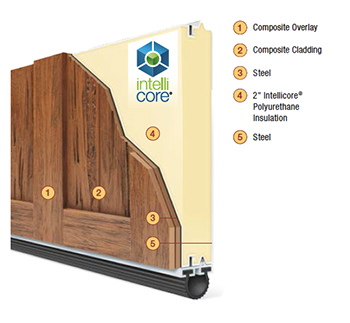

Wood’s natural insulation helps regulate garage temperatures. Homeowners report up to 20% lower energy costs compared to uninsulated metal doors 3. Adding foam or fiberglass insulation between plywood layers boosts this benefit, which is ideal for garages attached to living spaces 4.

Design Flexibility

Plywood’s smooth surface accepts stains, paints, and finishes effortlessly. Match your home’s architecture with rustic barn-door textures or sleek, minimalist panels 2. Custom carvings, window inserts, and panel configurations let you personalize every detail 6.

Budget-Friendly Repairs

You can often replace single damaged plywood panels for under $300, avoiding full-door replacements which is a cost metal doors rarely allow 38.

Selecting the Right Plywood Garage Door Panels

Understanding plywood’s benefits, let’s break down how to choose panels that align with your climate, style, and budget.

- Material Quality:

Climate Adaptations

Climate Adaptations

- Humid Regions: Opt for tropical hardwood veneers (e.g., teak) and epoxy-sealed edges to prevent swelling 12.

- Cold Climates: Insulated plywood-core doors with foam layers minimize heat loss.

- Sunny Areas: UV-resistant sealants (like marine-grade spar urethane) combat fading 13.

Design Harmony

- Traditional Homes: Raised or recessed panel designs complement classic architecture.

- Modern Styles: Flat-panel plywood with blackened steel accents aligns with 2025’s minimalist trends.

Maintenance Needs

Reseal plywood doors every 2–3 years. This is less frequent than solid wood but more than steel. For low upkeep, composite panels mimic wood textures with 50% less maintenance.

Custom vs. Standard Plywood Doors

Custom plywood garage doors cater to unique needs, while standard sizes (like 8x7 ft) suit most homes. Here’s how they compare:

| Feature | Custom Plywood Doors | Standard Doors |

|---|---|---|

| Design | Tailored dimensions, carvings, specialty finishes 6 | Pre-designed panels in common sizes 15 |

| Functionality | Smart tech integration, enhanced insulation 6 | Basic insulation and hardware |

| Cost | $2,500–$6,000+ (materials only) | $1,200–$3,000 (materials only) 1718 |

Custom designs shine in historic homes or unconventional openings, while standard panels offer affordability and faster installation.

Custom designs shine in historic homes or unconventional openings, while standard panels offer affordability and faster installation.

DIY Plywood Garage Door Installation: Cost-Saving Tips

Building your own plywood door rewards customization but demands precision.

Materials Needed

- Exterior-grade plywood (½" thickness)

- 2x4 lumber for framing

- Weatherproof wood glue, galvanized nails

- Heavy-duty hinges and rollers 19

Step 1: Measure and Frame

Cut 2x4s to match your door opening. Assemble a rectangular frame with corner braces, reinforcing joints with glue and screws 20.

Step 2: Attach Panels

Cut plywood to size and secure it to the frame. For insulation, layer foam board between plywood sheets 21.

Step 3: Add Hardware

Install hinges between panels (for sectional doors) and attach rollers. Test alignment to prevent jamming.

Step 4: Finish

Sand edges, apply primer, and stain or paint. Seal with marine varnish for weather resistance 22.

Pro Tip: Assemble panels on sawhorses to prevent warping during construction.

Common Mistakes to Avoid

- Using interior-grade plywood in humid climates (it lacks waterproof adhesives).

- Skipping UV sealants in sunny regions as this leads to premature cracking.

Maintaining Plywood Garage Door Panels

Preserve your door’s beauty and function with these practices:

- Biannual Cleaning

Wash with mild soap and water, then rinse. Avoid pressure washers because they strip finishes 2324.

Damage Checks

Inspect for soft spots (rot), cracks, or pests. Replace compromised panels promptly since delaying repairs can double costs 24.Refinish Every 2–3 Years

Sand lightly, fill gaps with wood putty, and reapply stain or paint. Use UV-blocking sealants for sun protection 13.Lubricate Moving Parts

Apply silicone spray to hinges and rollers annually for smooth operation.

Top 2025 Plywood Garage Door Innovations

This year’s trends blend sustainability with smart tech:

- VertiStack® Avante®: Award-winning design with interlocking plywood panels and built-in insulation 27.

- Clopay Canyon Ridge®: Plywood-core doors with steel overlays for dent resistance.

- Eco-Friendly Hybrids: FSC-certified plywood (sustainably sourced) paired with recycled steel supports 28.

Cost-Saving Strategies

- Pre-Fabricated Panels: Save 30–50% vs. custom designs 8.

- Material Mixing: Use plywood for visible sections and steel for structural supports 30.

- DIY Installation: Skilled homeowners save $300–$500 on labor 17.

The Future of Plywood Garage Doors

2025’s trends focus on eco-smart solutions and bold aesthetics:

- Mixed Materials: Plywood paired with tempered glass or blackened steel boosts curb appeal and resale value.

- Smart Tech: App-controlled openers sync with home security systems 32.

- Low-VOC Finishes: Healthier for families and the environment 28.

Final Thoughts

Plywood garage door panels offer timeless appeal, resilience, and adaptability. By choosing quality materials, maintaining them proactively, and embracing 2025’s innovations, you’ll create a functional centerpiece that elevates your home’s value. For best results, consult a certified installer to align your design with local climate demands. Even if it’s DIY or custom-built, a well-crafted plywood garage door withstands multiple years of use while reflecting your unique style.